+Production

Thanks to these unconventional techniques, today it is possible to produce oil and gas trapped in formations that until recently were considered unproductive.

Vaca Muerta could end up supplying the entire country’s energy needs

Argentina ranks 3rd in the world in terms of the size of recoverable unconventional gas resources

Thanks to national production, gas imports can be reduced by as much as 75%

For more information, visit the Tecpetrol website

BrowseVaca Muerta is the country’s leading unconventional gas play, singular not only from the point of view of the energy it supplies, but also because of the many stories the area tells. Find out more about them.

These drilling rigs differ from traditional ones regarding the system used to move them from one wellhead to another. They slide across the ground thanks to large-capacity hydraulic cylinders that push the rig over greased steel skid beams. This means that the rig does not have to be disassembled, transported and then reassembled.

Reduces transfer time by up to 80%

Reduces mobilization and transportation costs

Reduces times which means production can begin earlier

xxxx

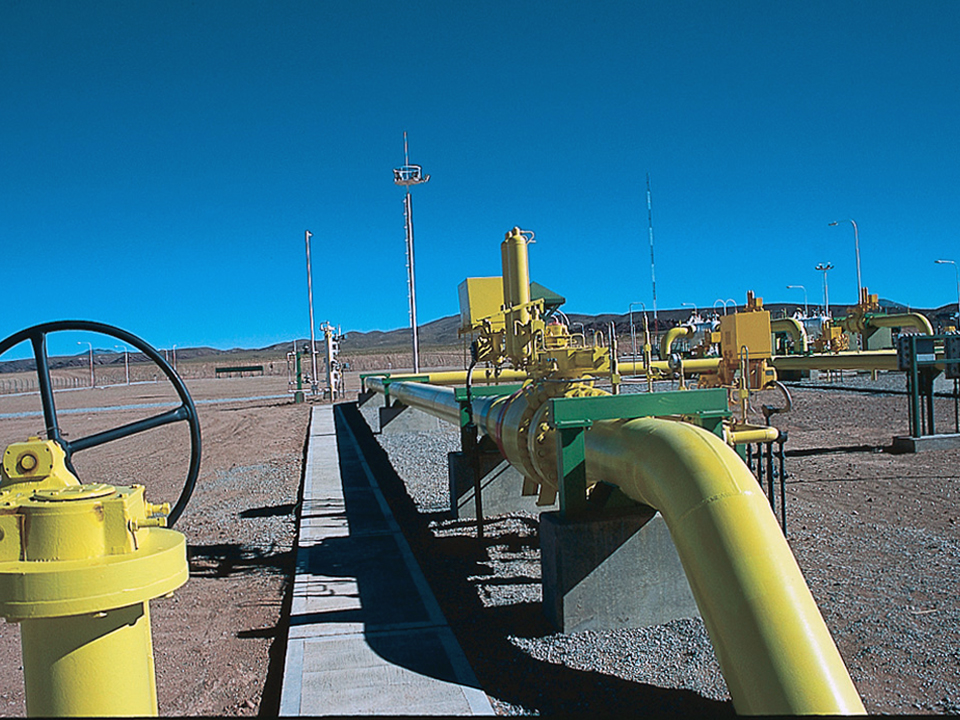

In order to condition the gas to meet the sales specifications required by the national transportation system, it is processed at the Fortín de Piedra Central Plant, which has 9 compressors and a processing capacity of 17.5 million m3/day of gas.

Stabilization is performed to remove the light components, leaving the liquid hydrocarbons in conditions of sale.

In one sector of the plant, up to 1,000 m3/d of oil can be loaded (which is equivalent to 30 tanker trucks per day).

Any remaining liquid hydrocarbons and salts are removed. The treated water is injected into sinkholes at a depth of 1,500 meters.

Water treatment capacity: 3,000 m3/d.

The sand is sourced from the provinces of Entre Ríos and Chubut and transported to the Sand Distribution Center, some 15 km away from the wells. This route is known as "the last mile" as it is the stretch along which the trucks bearing the materials to the hydraulic fracturing rigs circulate. The development of an area the size of Fortín de Piedra requires an amount of sand equivalent to a 70-story building covering a surface area of one hectare. The difficulty lies in transporting such a volume of materials, as at the peak of production, some 20,000 tons of sand need to be moved. It is key to protect sand quality to avoid problems arising during the process.

At the peak of production, some 20,000 tons of sand need to be moved.

It is key to protect sand quality to avoid inconveniences arising during the process.

When undertaking an accelerated shale project, it’s critical to ensure a plentiful supply of water. At Fortín de Piedra, the water is brought from the Neuquén river and stored in large tanks containing up to 20,000 m3 of water before being piped to the fracturing rig. Once there, the water is mixed with additives and sand in the blender for the fracturing process.

Some 1,500 m3 of water are used per fracture operation.

The water used to develop the project over 10 years would only represent 0.12% of the river’s total flow.

In Vaca Muerta, drilling is carried out in stages to make the most of efficient mobilization such as that offered by rig skidding systems. This ensures resources can be optimized and major savings achieved during the process to commercialize unconventional hydrocarbons.

Drilling is done in four casing sections. The gas circulates to the surface through the production casing. When formation pressure drops, narrower tubing is inserted downhole to encourage it to flow.

Different bits are used depending on the terrain.

Geosteering uses realtime geological and geophysical measurements to manage the optimal placement of the wellbore when drilling horizontally. This means that the whole process can be achieved faster and with far greater precision. Thanks to geosteering, lateral branches of wells can be drilled into the area of the reservoir with the greatest production potential.

Detailed analysis of the reservoir area where the proposed horizontal well is expected to be drilled

This is the entry point to the reservoir, where the horizontal navigation or geosteering process begins

Some 2,500 meters of wellbore is drilled into the productive oil sands once the landing point is completed

To drain the hydrocarbons trapped in the formation, hydraulic fracturing is undertaken to create high permeability channels. The idea is to find the optimal spacing between fractures in the horizontal branch allowing for optimum fluid recovery. The most common technology used in unconventional reservoirs is called plug-and-perf or limited entry, which involves pumping down a bridge plug on a wireline with perforating guns.

Water and sand are pumped into the formation through the perforations in the rock.

High permeability channels are created, allowing hydrocarbons to flow back into the well and then up to the surface.

The Vaca Muerta formation has very low permeability, and therefore requires non-traditional extraction techniques such as horizontal wells, geosteering and hydraulic fracturing. This creates channels throughout the formation which allow the hydrocarbons to flow out for commercial production.

Thanks to these unconventional techniques, today it is possible to produce oil and gas trapped in formations that until recently were considered unproductive.

Using hydraulic rig skidding systems means that moving from one wellhead to the next is a much easier and faster process, as the whole rig can simply be skidded along beams between slots, reducing time and costs and bringing production forward

The pad scheme implemented with multiple well bay slots per location substantially minimizes environmental impact since there is less need to intervene the land.

The main unconventional hydrocarbons reservoir in Argentina, the Vaca Muerta formation covers an area of 30,000 km2, stretching into the provinces of Neuquén, Río Negro, La Pampa and Mendoza.

Fortín de Piedra achieved an output of 24 million m3/day of gas. This means 15% of the produced in Argentina, enough to power some 2,300,000 homes.

Vaca Muerta's potential would make it possible to substitute fuels currently imported from other countries, such as Qatar, with domestic supply. Fortín de Piedra has helped us take another major step forward to self-sufficiency.

The new gas from Vaca Muerta has meant that Argentina has been able to significantly reduce its reliance on imports, and in addition, it has begun exporting energy to Chile. Fortín de Piedra is thus contributing to improving the national energy balance.

Producing more gas has meant the price of this fuel has fallen in line with increased supply.

In just 18 months, Tecpetrol, together with the efforts of 1,000 companies from over 15 Argentine provinces, made the Fortín de Piedra project a reality. In this way, hard currency remains in the country.

Natural gas used for electricity generation is more environmentally friendly than other fossil fuels used for this purpose.

Fortín de Piedra forms part of a virtuous circle with a positive effect for the country. Here we tell you why our Vaca Muerta site is so vital for Argentina.